RFS Strut

RFS Strut

The 41mm RFS Strut works with all cable and pipe support systems. But the huge benefit to you is that it is locally made, right here in New Zealand. This means shorter lead times, no shipping headaches, and you can order exactly what you need for your job, and have it delivered to your site on the day that you need it.

Nor do you have to order it by the container load; you can order just what you need to get the job done. That means less wastage, shorter delivery times and no international shipping and storage costs.

We are just around the corner, not the other side of the earth.

We can manufacture the 41mm wide RFS Strut in a range of thicknesses, heights and materials, suitable for light, medium or heavy-duty applications. You just tell us what you need for your job and we can create it for you.

Our cut-to-length service means you have the exact size for your installations without the need to cut the down the 6m lengths yourself onsite. There is no waste – we supply just what you need.

What is more, to save you time and hassle, we can bundle in lots of various lengths specific to each installation, so there is no need to sort through your order hunting for the right lengths.

Generally, it is used to support electrical and plumbing products (such as cable tray/ladder, lighting rig, HVAC installations or pipe clamps) but can be used for all manner of things. Its strength and adaptability also allow for many different uses. The channel the RFS Strut creates provides an ideal mechanical support frame.

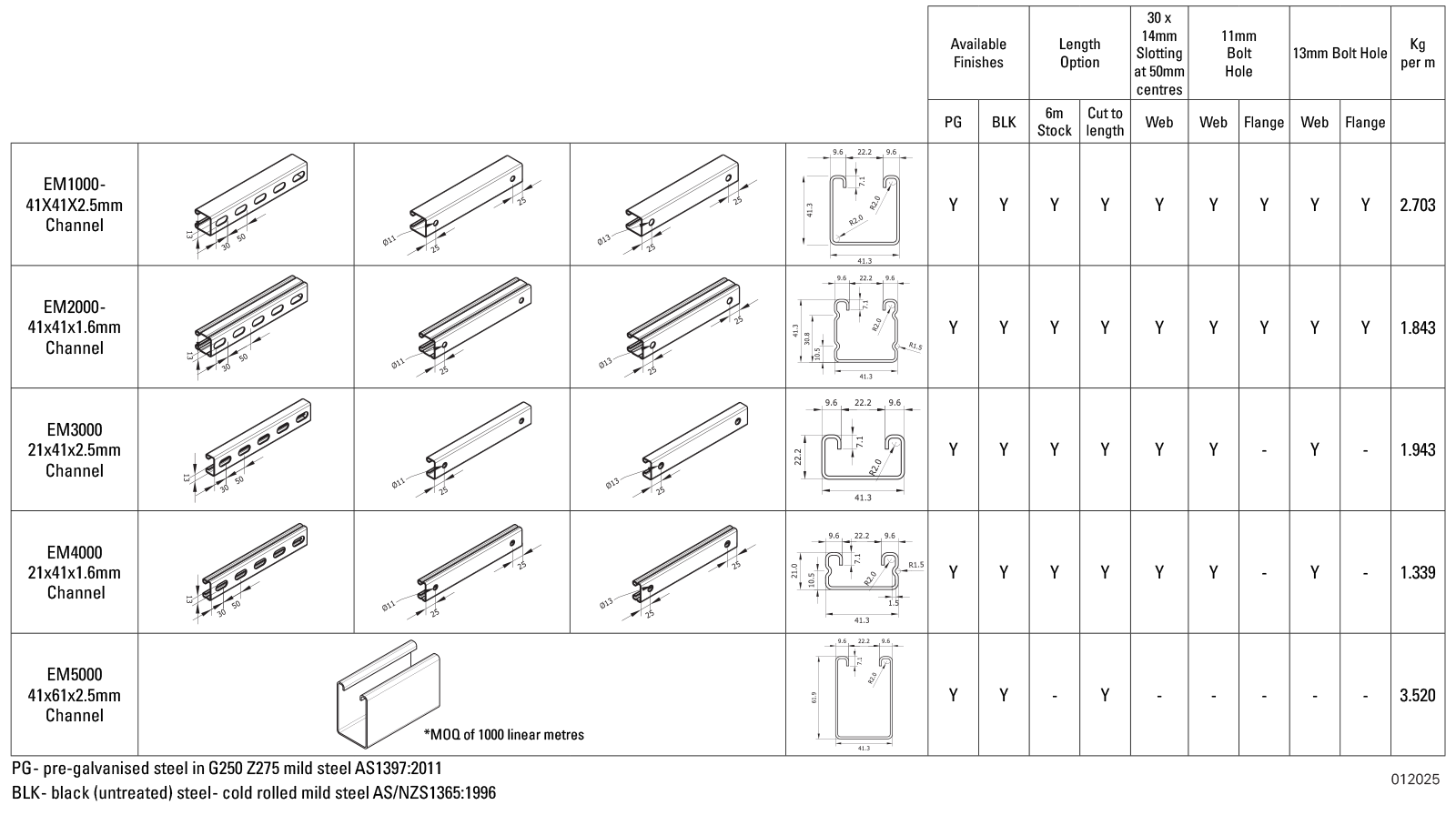

Struts is available in two finishes - pre-galvanised (PG) or black (BLK) steel

Pre-galvanised (PG) steel is G250 Z275 galvanised coated mild steel AS1397:2011.

Black or untreated (BLK) steel is cold rolled mild steel AS/NZS1365:1996, which allows you to fabricate and weld to your requirements before applying coating

The RFS Struts are available in the following range:

- Plain or slotted

- Heights - 21mm, 41mm, 61mm

- Thickness - 2.5mm, 1.6mm

- Length – 6m standard stock lengths with same day pick-up, or cut to any length with approximately 5-day lead time

- 30x13mm slotting holes at 50mm centres

- 11mm bolt holes in the web and flange

- 13mm bolt holes in the web and flange

Trapeze lengths which suit standard cable tray sizes are available to order in bulk quantities, or to suit specific projects. Talk to us about these.

- 300mm for 150mm cable tray

- 450mm for 300mm cable tray

- 600mm for 450mm cable tray

- 750mm for 600mm cable tray

If you choose to have RFS Struts delivered early or you do not have time to finish the job, take care to store your RFS Struts properly. They must be kept dry as water present between close stacked sections will cause premature corrosion. If they do become wet, make sure to separate and stack them openly to allow for ventilation to dry the surface.

Run-off from, or contact with, materials which are incompatible with zinc should be avoided.

Get in touch

We encourage you to furnish us with as much detail as possible.

That way we can assist you with the best solutions based on your requirements quickly.