Residential Roof Purlins

Residential Roof Purlins

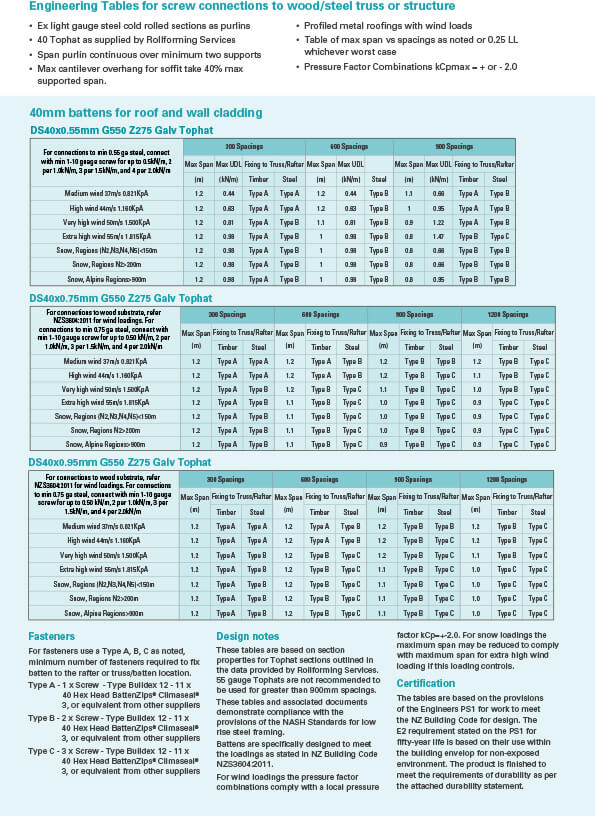

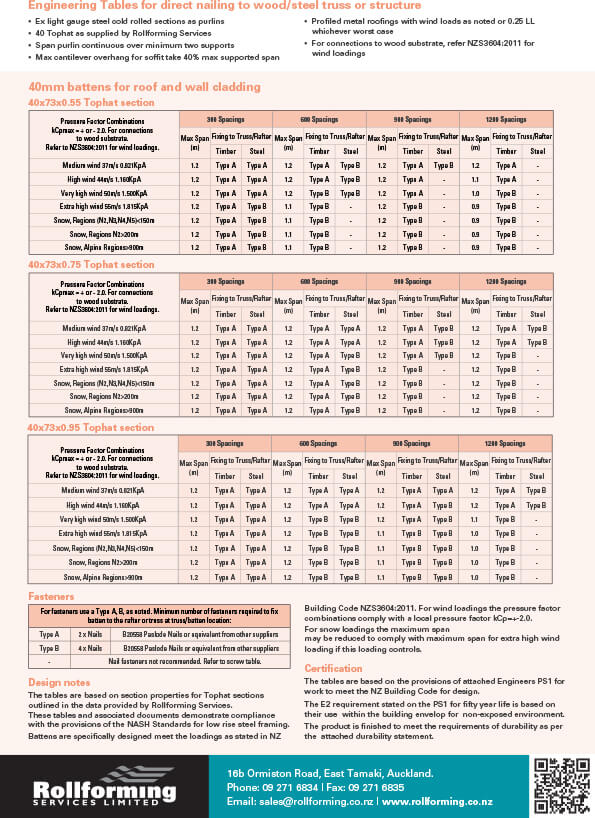

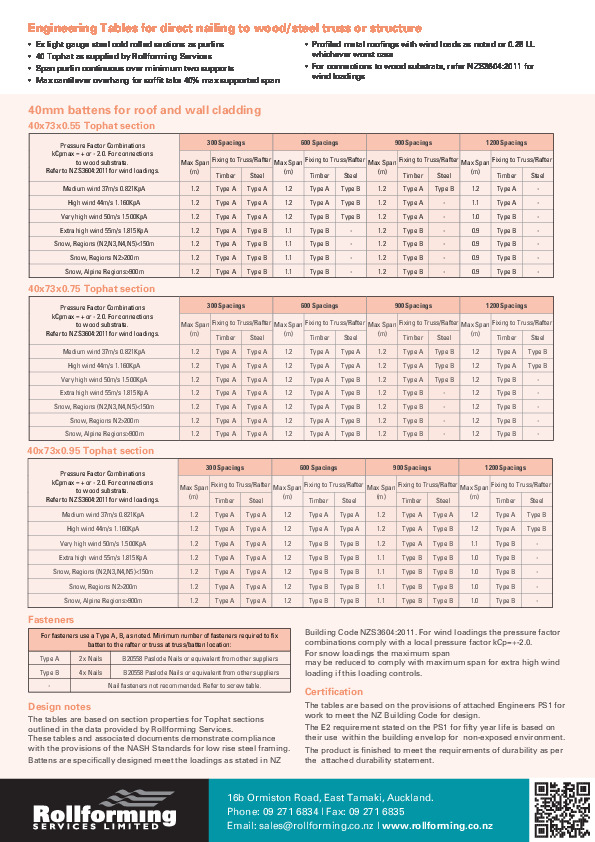

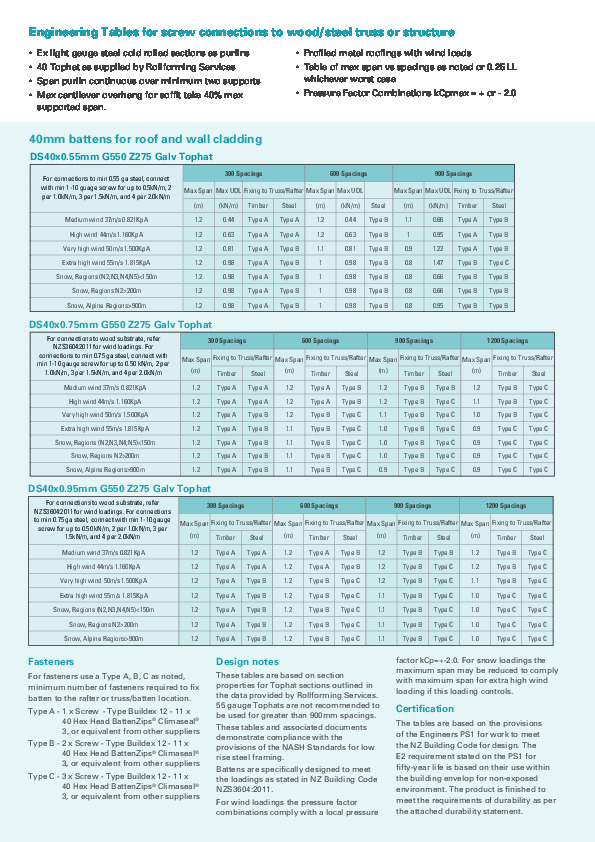

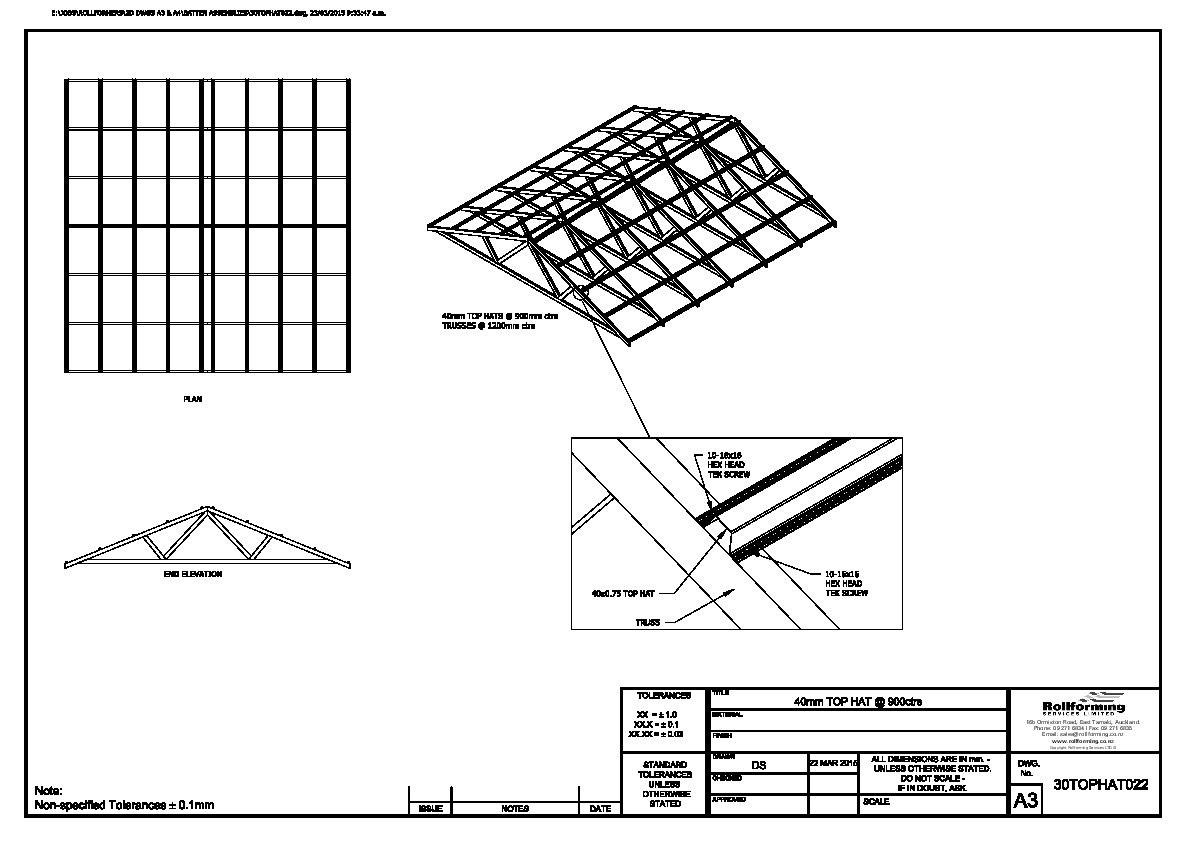

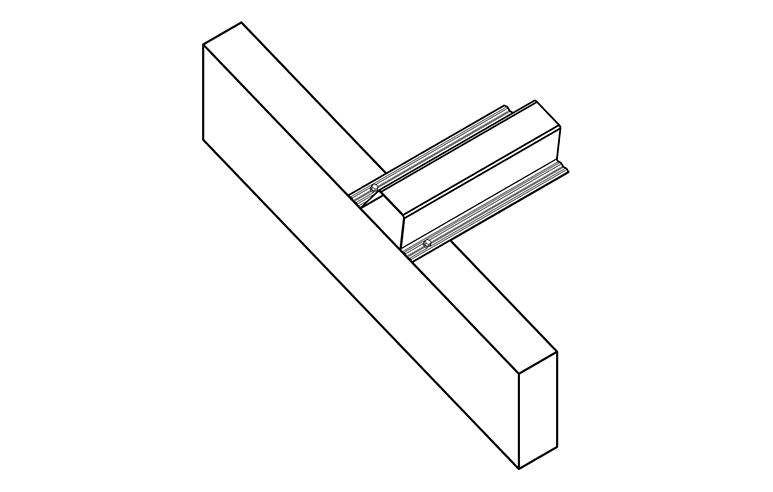

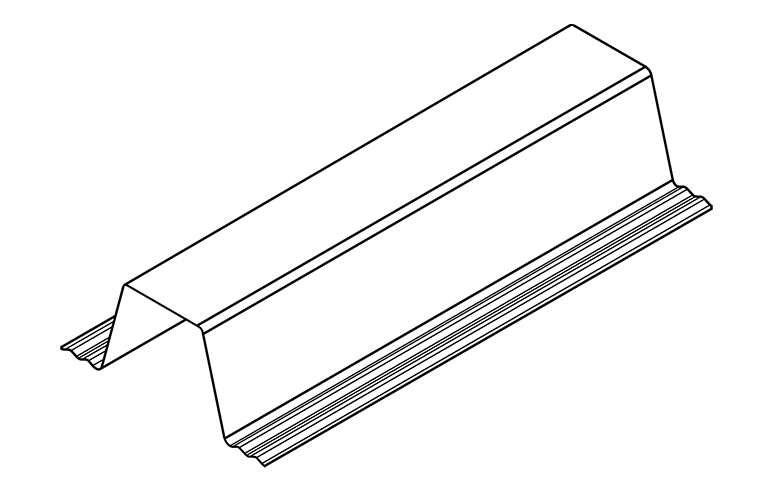

Rollforming Services' 40mm Roof Purlins are a direct replacement for timber purlins. They are lightweight, dimensionally stable, accurate and straight. They expand and contract at the same rate as steel roofing products in extreme temperature changes. They can be fitted to both timber and steel trusses with Type 17 Teks. Ideally suited to timber framed homes, steel framed homes, steel framed buildings and carports.

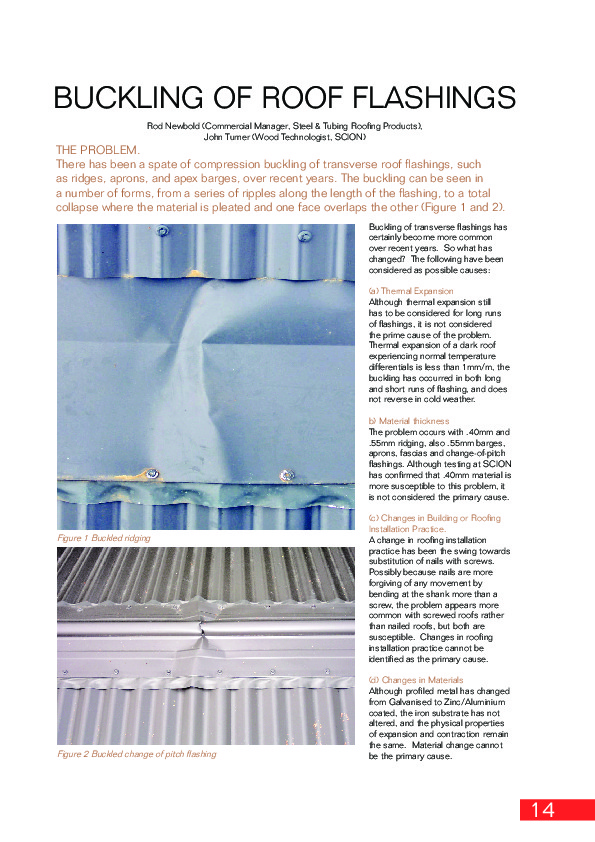

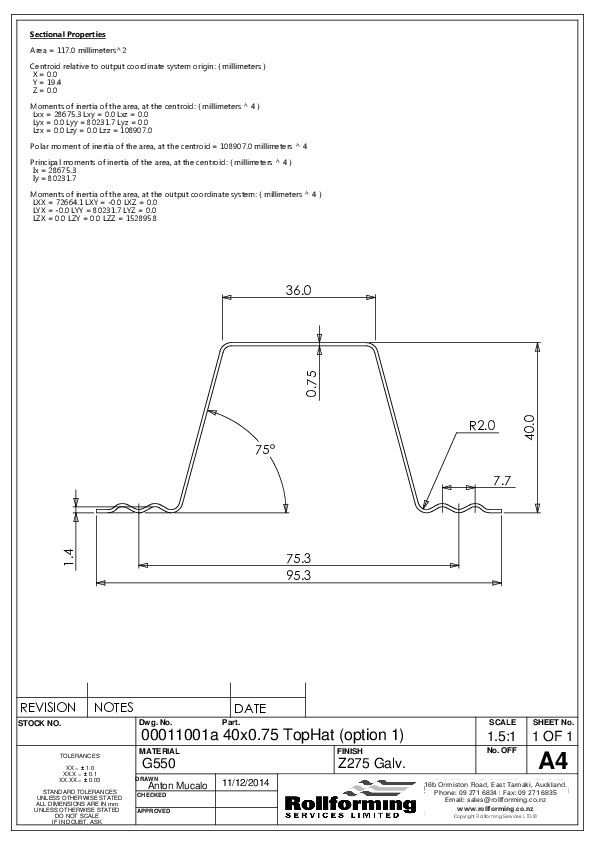

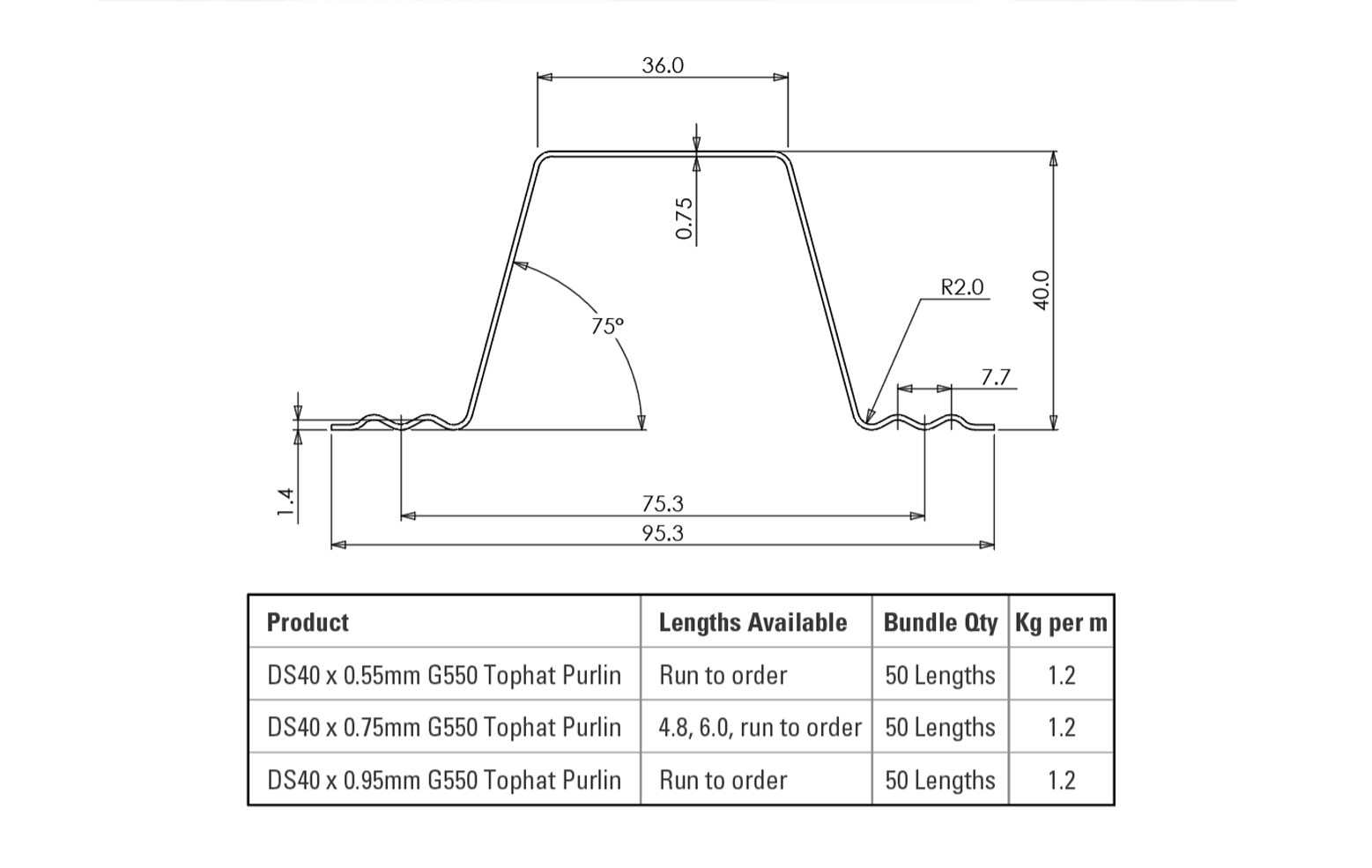

As a direct replacement for timber purlins, RFS DS40 40mm Residential Roof Purlins offer a number of distinct advantages. At just 0.965 kg per metre, they are light, dimensionally stable, accurate and straight. Because they expand and contract at the same rate as other steel roofing products in extreme temperatures, they do not produce the buckling ridge.

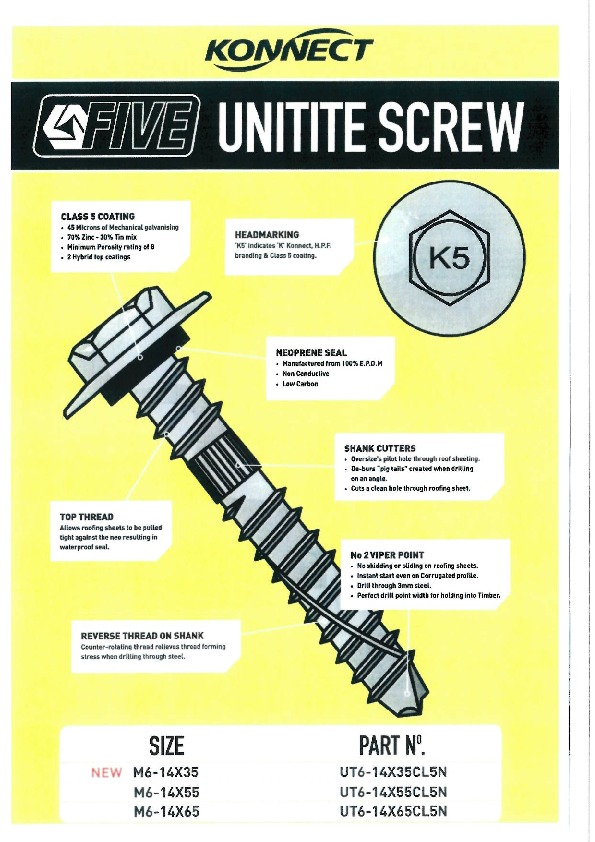

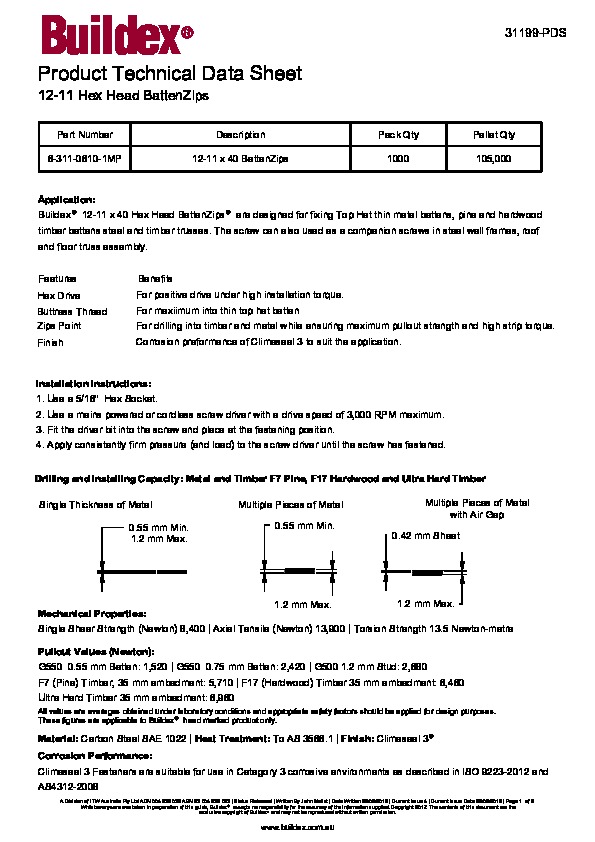

DS40 Purlins are ideal for steel or timber framed homes, buildings and carports. They can be fitted to both timber and steel trusses with screws, or nailed directly to timber trusses.

With spans of 1200mm at 900mm spacings they can be used in extra high wind zones and where snow loads are present. Lengths are available from stock or you can choose to have them run cut-to-length of up to 12m to reduce waste onsite. For larger spans, check out our Tophat Purlin range.

DS40 Purlins are manufactured from hot dipped, galvanised G550 Z275 steel at thicknesses of 0.75mm, 0.95mm or 1.15mm. The coating weight of 275 gram/sqm is in line with other lightweight steel structural building products, providing good protection in most exposed internal environments.

The product is finished to meet durability requirements and backed by the New Zealand Steel Durability Statement. The E2 requirement stated on the PS1 for fifty-year life is based on their use within the building envelope for non-exposed environments.

Steel roof purlins must be kept dry as any water present between close stacked sections will cause premature corrosion. If they become wet, the purlins should be separated and stacked openly to allow for ventilation to dry the surface. Any run off from, or contact with, materials which are incompatible with zinc should be avoided.

Cutting is preferably done by shear or hacksaw. When using abrasive disc blades, care must be taken to ensure the swarf produced does not affect other materials and the burred edge should be cleaned off at the completion of cutting. Finish the cut end with a galv spray for added protection.

Get in touch

We encourage you to furnish us with as much detail as possible.

That way we can assist you with the best solutions based on your requirements quickly.