RFS Back To Back Strut

RFS Back to Back Strut

RFS Back to Back Struts are riveted together during the cold-formed steel rolling process, saving you time and money. There is no need for welding or additional galvanising. They are compatible with all cable and pipe support systems, can accommodate more cabling and piping by being double-sided, and they are made in New Zealand. You can order what you need, when you need it, and be confident it will turn up on time without the wastage involved in bulk ordering, international shipping, and storage.

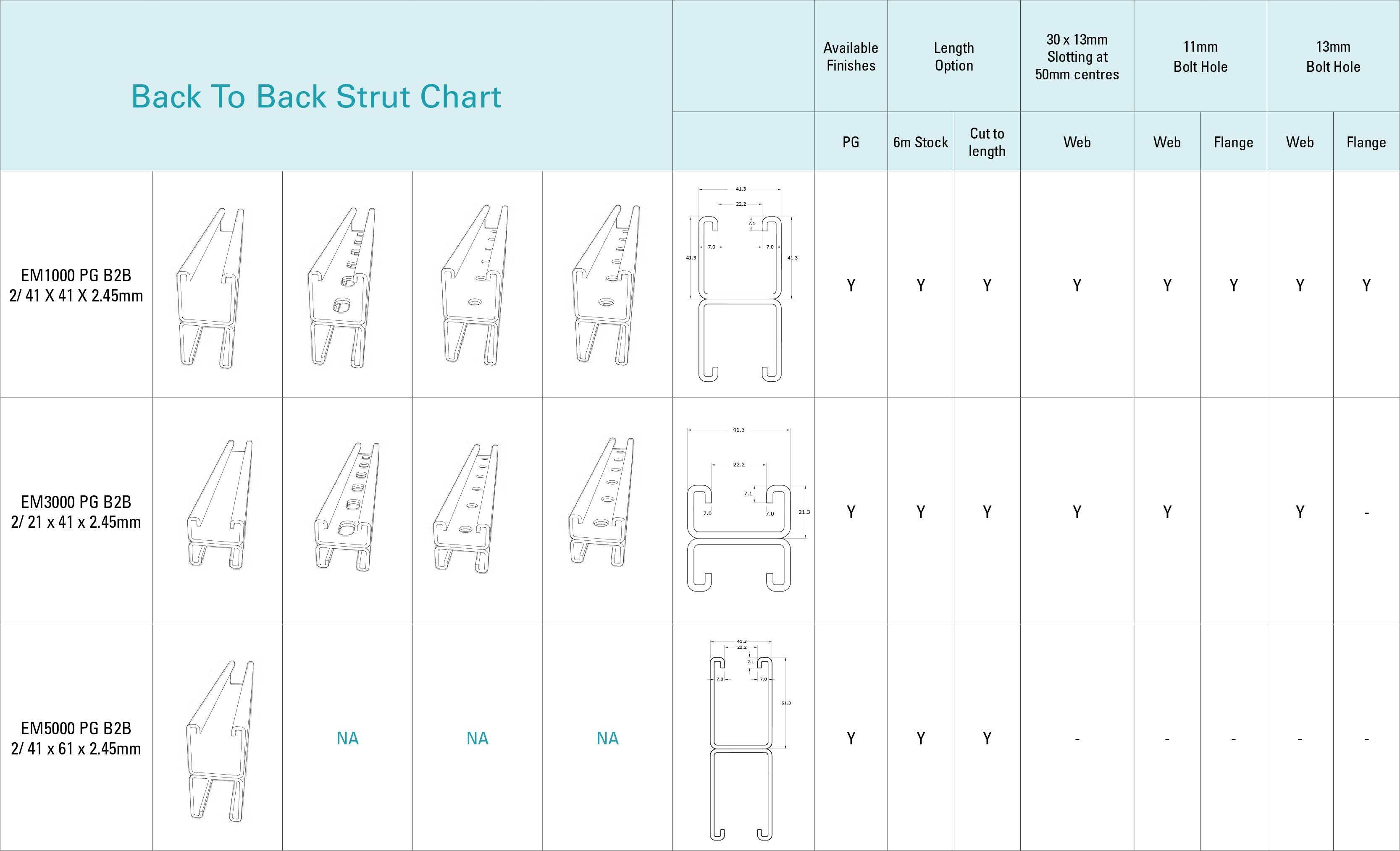

Made from 2.45mm pre-galvanised steel, the RFS Back to Back Strut system comprises 41mm wide channel sections that can be easily assembled, reconfigured and modified using brackets, rivets or bolts. With 3 different height options, the struts are suitable for light, medium or heavy-duty applications.

Our cut-to-length service means you have the exact size for your installations without the need to cut down 6m lengths yourself onsite. As well as convenience, the benefit is practically zero wastage. We supply just what you need and we can bundle your order in lots of various lengths specific to each installation. That means no more sorting through your order to find the right lengths.

The channels the RFS Back to Back Strut creates provides a versatile mechanical support frame for electrical and plumbing products (such as cable tray/ladder, lighting rig, HVAC installations or pipe clamps). Their superior strength and adaptability make RFS Back to Back Struts suitable for many different uses.

RFS Back to Back Struts are available pre-galvanised (PG). Pre-galvanised steel is G250 Z275 galvanised coated mild steel AS1397:2011.

If you need to store your RFS Back to Back Struts for any length of time, it is important to follow the correct storage procedure. The struts must be kept dry as any water present between closely stacked sections may cause premature corrosion. If they do become wet, make sure to separate and stack them openly to allow for ventilation to dry the surface. Run-off from, or contact with, materials which are incompatible with zinc should be avoided.

Get in touch

We encourage you to furnish us with as much detail as possible.

That way we can assist you with the best solutions based on your requirements quickly.